Osha Rigging Fact Sheet

Osha Rigging Fact Sheet - When is a qualified rigger required? The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. Employers must use qualified riggers during hoisting activities for assembly and disassembly work. Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. Integrating patient and workplace safety programs.

When is a qualified rigger required? Employers must use qualified riggers during hoisting activities for assembly and disassembly work. Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. Integrating patient and workplace safety programs.

Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. Integrating patient and workplace safety programs. The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. Employers must use qualified riggers during hoisting activities for assembly and disassembly work. When is a qualified rigger required?

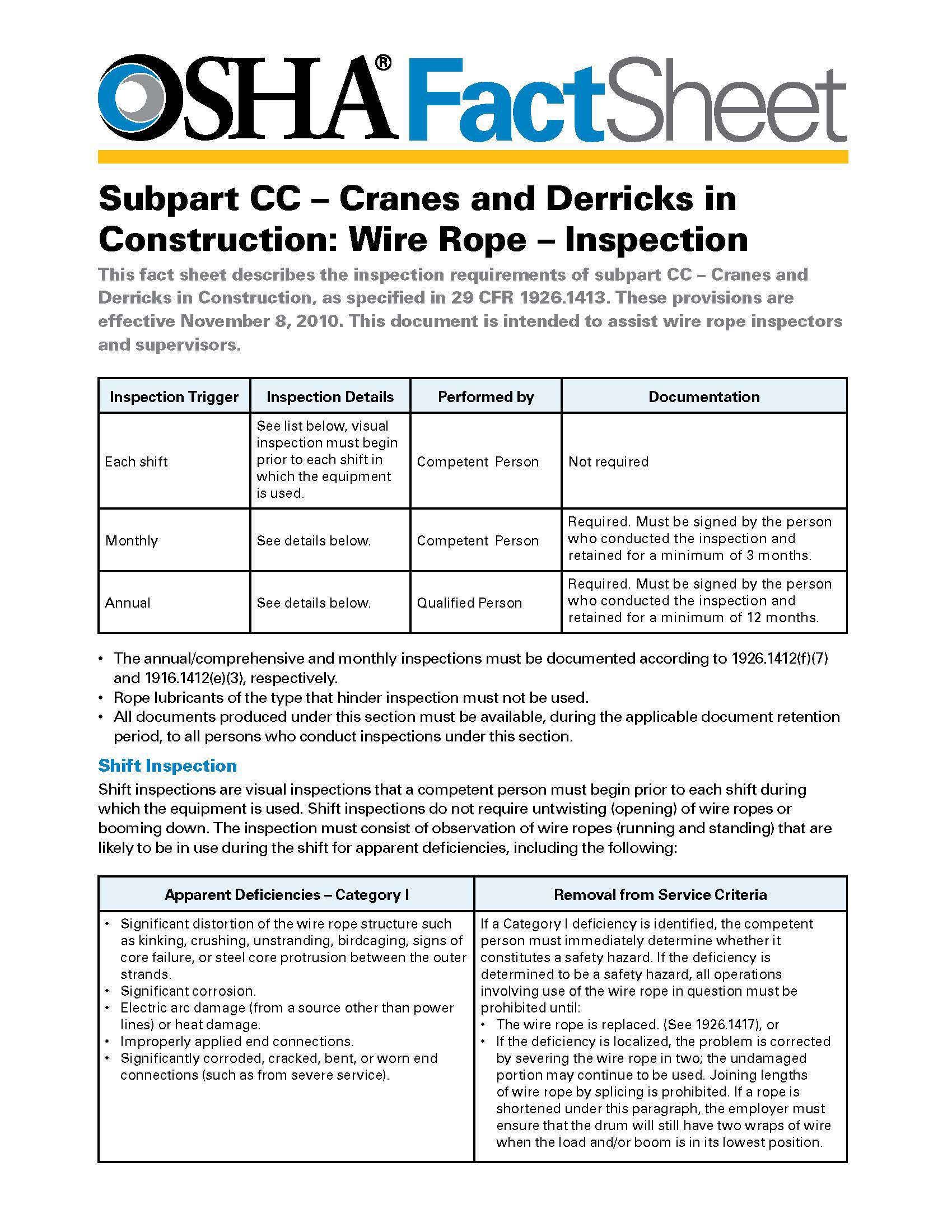

OSHA Facts Cranes and Derricks in Construction Wire Rope Inspection

Employers must use qualified riggers during hoisting activities for assembly and disassembly work. The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use.

OSHA Inspections Fact Sheet Profiting From Safety

The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. Employers must use qualified riggers during hoisting activities for assembly and disassembly work. Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use.

Lockout Tagout Osha Fact Sheet

Integrating patient and workplace safety programs. The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. Employers must.

Osha Cranes And Hoists at Margie Hill blog

Employers must use qualified riggers during hoisting activities for assembly and disassembly work. Integrating patient and workplace safety programs. Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. The qualified rigger fact sheet is a guide for determining if a worker is qualified to.

OSHA Fact Sheet Fire Safety in the Workplace DocsLib

Integrating patient and workplace safety programs. Employers must use qualified riggers during hoisting activities for assembly and disassembly work. When is a qualified rigger required? The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. Rigging equipment for material handling shall be inspected.

Rigging Fact Sheet for Training Employees and Employers ClickSafety

The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. When is a qualified rigger required? Integrating patient and workplace safety programs. Employers must use qualified riggers during hoisting activities for assembly and disassembly work. Rigging equipment for material handling shall be inspected.

OSHA Fact Sheet Reducing Falls in Construction Safe Use of Stepladders

The qualified rigger fact sheet is a guide for determining if a worker is qualified to properly rig the load for a particular job, and the signal. When is a qualified rigger required? Integrating patient and workplace safety programs. Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to.

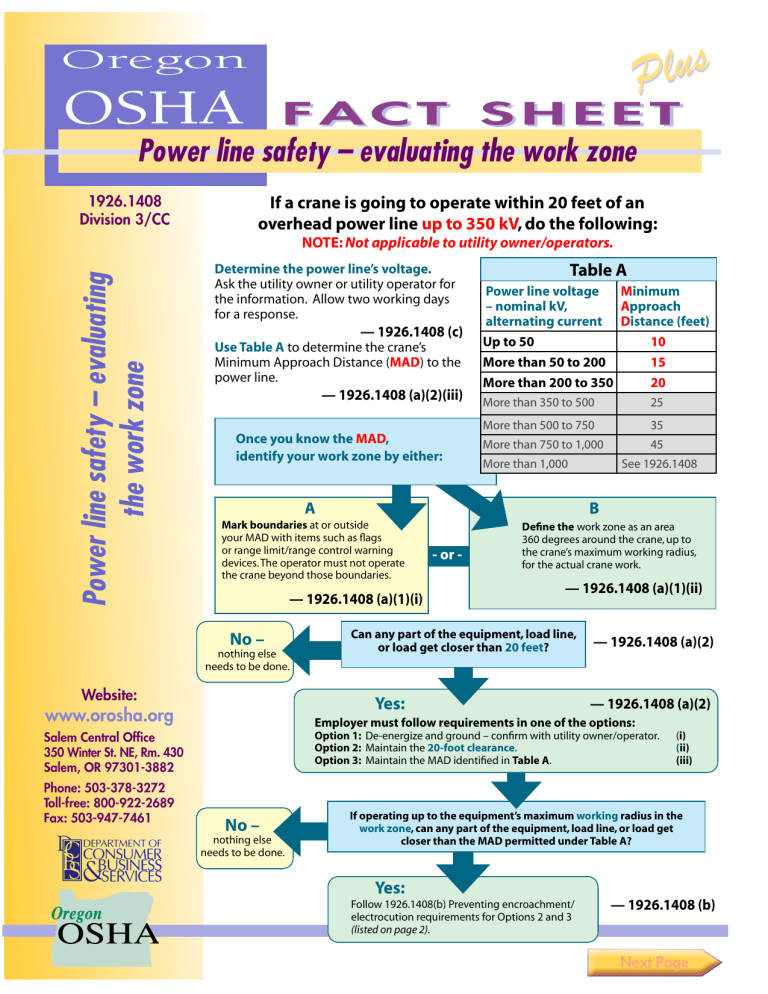

OSHA FACT SHEET Power line safety evaluating the work zone

Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. Integrating patient and workplace safety programs. Employers must use qualified riggers during hoisting activities for assembly and disassembly work. The qualified rigger fact sheet is a guide for determining if a worker is qualified to.

Osha Rules For 2024 Cyndi Dorelle

Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. When is a qualified rigger required? Employers must use qualified riggers during hoisting activities for assembly and disassembly work. Integrating patient and workplace safety programs. The qualified rigger fact sheet is a guide for determining.

Rigging Fact Sheet for Training Employees and Employers ClickSafety

Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. Employers must use qualified riggers during hoisting activities for assembly and disassembly work. Integrating patient and workplace safety programs. The qualified rigger fact sheet is a guide for determining if a worker is qualified to.

The Qualified Rigger Fact Sheet Is A Guide For Determining If A Worker Is Qualified To Properly Rig The Load For A Particular Job, And The Signal.

Integrating patient and workplace safety programs. When is a qualified rigger required? Rigging equipment for material handling shall be inspected prior to use on each shift and as necessary during its use to ensure that it is. Employers must use qualified riggers during hoisting activities for assembly and disassembly work.