What Is Wire Bonding

What Is Wire Bonding - Wire bonding is a method of making interconnections between an integrated circuit (ic) or other semiconductor device and its packaging during semiconductor device fabrication. Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Explore the types, process, and applications of wire bonding in pcb assembly. Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Let’s delve into its process flow, the differences from traditional wire soldering, the required.

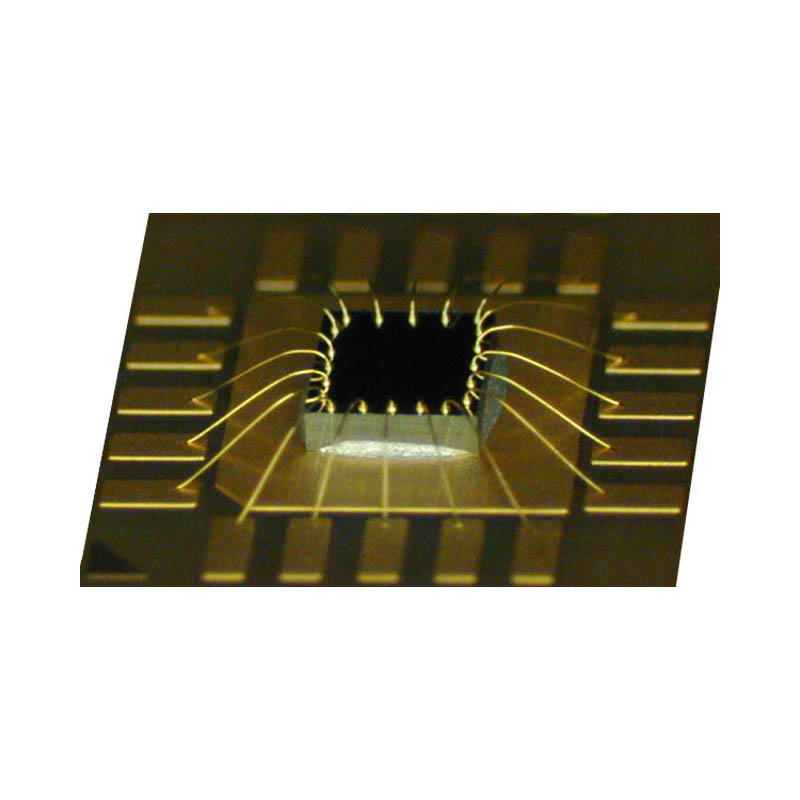

Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Explore the types, process, and applications of wire bonding in pcb assembly. Let’s delve into its process flow, the differences from traditional wire soldering, the required. Wire bonding is a method of making interconnections between an integrated circuit (ic) or other semiconductor device and its packaging during semiconductor device fabrication. Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic.

Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Let’s delve into its process flow, the differences from traditional wire soldering, the required. Wire bonding is a method of making interconnections between an integrated circuit (ic) or other semiconductor device and its packaging during semiconductor device fabrication. Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic. Explore the types, process, and applications of wire bonding in pcb assembly.

WireBonding Semiconductor Backend Process and Packaging INGS

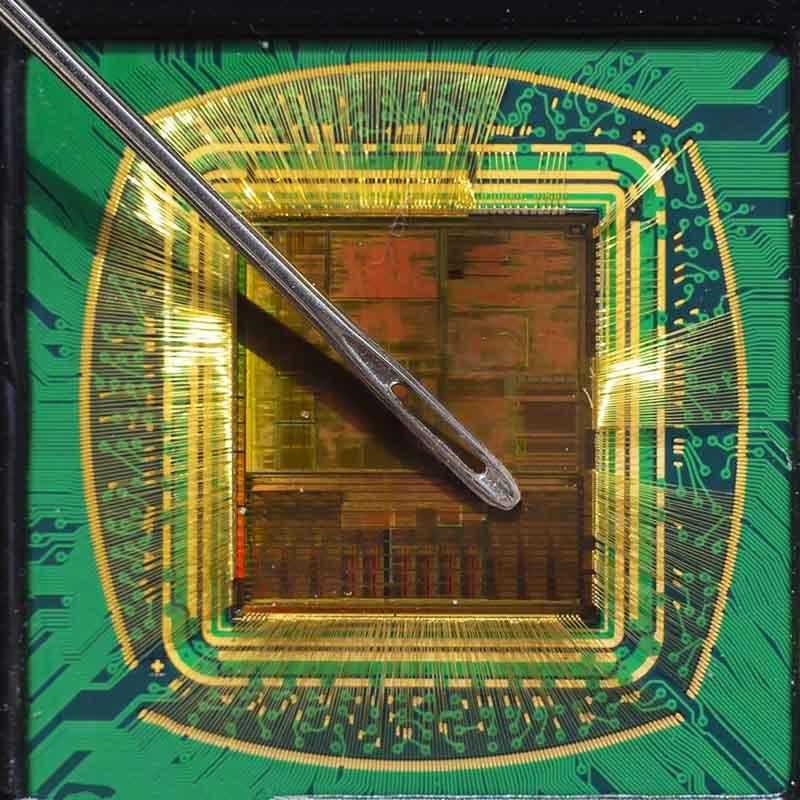

Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Learn how viasion utilizes wire.

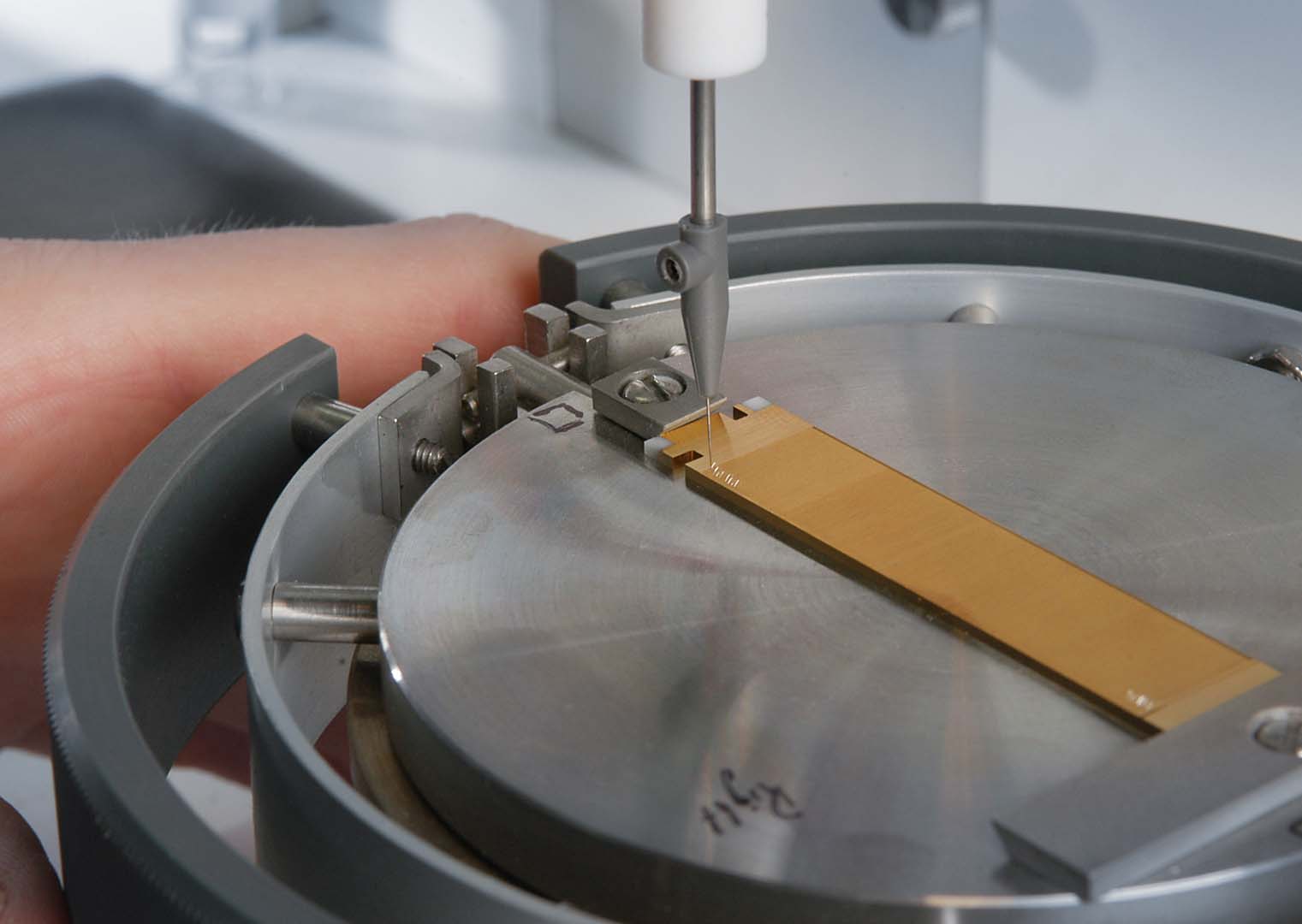

Wire Bonding Services Alter Technology (formerly Optocap),

Let’s delve into its process flow, the differences from traditional wire soldering, the required. Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Explore the types, process, and applications of wire bonding in pcb assembly. Wire bonding is the process of.

Wire Bonding Efficient Interconnection Technique Sierra Circuits

Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic. Explore the types, process, and applications of wire bonding in pcb assembly. Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Let’s delve into its process flow, the differences.

Wire Bonding ICT

Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic. Explore the types, process, and applications of wire bonding in pcb assembly. Let’s delve into its process flow, the differences from.

Improve Wire Bond Capability and Reliability Through Use of Auxiliary Wires

Explore the types, process, and applications of wire bonding in pcb assembly. Wire bonding is a method of making interconnections between an integrated circuit (ic) or other semiconductor device and its packaging during semiconductor device fabrication. Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to.

wire bonding Wire Bonding PCB Rocket PCB

Wire bonding is a method of making interconnections between an integrated circuit (ic) or other semiconductor device and its packaging during semiconductor device fabrication. Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Let’s delve into its process flow, the differences.

Wire Bonding ICT

Wire bonding is a method of making interconnections between an integrated circuit (ic) or other semiconductor device and its packaging during semiconductor device fabrication. Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine.

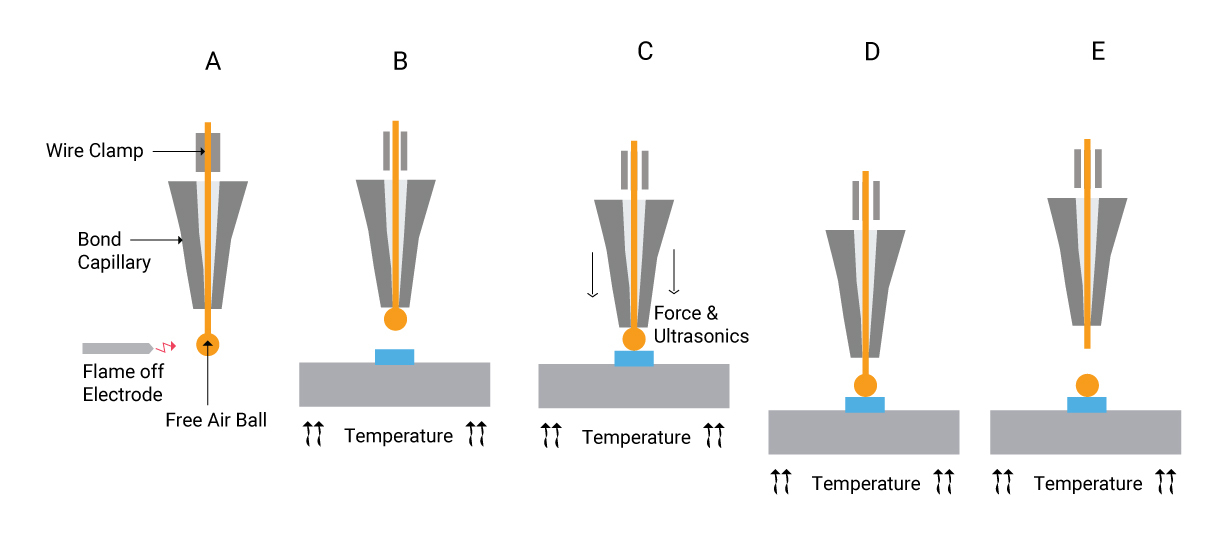

What is the Wire Bond Process

Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Explore the types, process, and applications of wire bonding in pcb assembly. Let’s delve into its process flow, the differences from.

What is Wire Bonding? RAYPCB

Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Let’s delve into its process flow, the differences from traditional wire soldering, the required. Explore the types, process, and applications of.

Wire Bonding Pcb Wire Bonding Enepig Surface Finished Pcb

Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Wire bonding is a method of making interconnections between an integrated circuit (ic) or other semiconductor device and its packaging during semiconductor device fabrication. Learn how viasion utilizes wire bonding techniques for reliable.

Explore The Types, Process, And Applications Of Wire Bonding In Pcb Assembly.

Wire bonding uses thin metal wires to use heat, pressure, and ultrasonic energy to tightly weld metal leads to substrate pads, so as to realize electrical interconnection between. Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of. Let’s delve into its process flow, the differences from traditional wire soldering, the required. Learn how viasion utilizes wire bonding techniques for reliable and efficient electronic.